3 Simple Techniques For Sheroz Earthworks

3 Simple Techniques For Sheroz Earthworks

Blog Article

Get This Report on Sheroz Earthworks

Table of ContentsExcitement About Sheroz EarthworksNot known Incorrect Statements About Sheroz Earthworks The Buzz on Sheroz EarthworksThings about Sheroz EarthworksUnknown Facts About Sheroz Earthworks

For any type of earthwork contractor, it is important to do collaborate with quality, accuracy, and on timetable. Utilizing maker control in job equipments enables enhancing the different phases in the earthwork procedure, from preparing to the upkeep phase - fj dynamics autosteer review. The equipment control system aids the maker driver in attaining the target plane promptly and quickly

The device control system overviews the driver with centimeter accuracy. Remote support saves time and cash, as it reduces downtime in jobsites.

The Best Strategy To Use For Sheroz Earthworks

Extra training and guidelines are always offered over remote support when needed. The earthmoving industry has actually used our field-proven options given that the early 1990s. Our system's parts are thoroughly created to stand up to the rough problems of construction websites. Comparison of the exact same job performed making use of equipment control versus the traditional approach exposes that, on average, the typical approach needs 50% more time to complete the exact same job as the technology-assisted approach. https://myspace.com/sherozau.

Appears great? Enter the Xsite machine control system; it's here to give you with a considerable benefit when dealing with earthmoving machinery. Discover just how Xsite Equipment Control can boost your performance and guarantee job safety! We recognize that finding out a brand-new modern technology may seem like a drag, but don't fret! Our pleasant and expert neighborhood support solutions have got you covered, making sure that you can keep functioning smarter without disturbances while on the task! With remote support, your local Xsite supplier can provide advice or troubleshooting without having to visit the site! What type of excavators does equipment control fit? Xsite Device Control systems can be installed to any type of excavator from mini excavators to big mining excavators.

Just how does maker control work? In 2D systems, the maker is furnished with adjusted disposition sensing units.

The system is very simple to learn the essentials can be instructed in under one hour of training. With Xsite you don't have to fret about finding out all the tips and trick at once. Additional training and instructions are constantly offered over remote support when required. Get in touch with your regional Xsite dealer to figure out even more! Just how does the remote assistance work? A wireless internet connection makes it possible to establish a remote link between the equipment control system and the solution facility.

Unknown Facts About Sheroz Earthworks

What type of data layouts Xsite systems support? Xsite Maker Control systems sustain open conventional data formats, making it possible for seamless info flow from one system to one more. Sustained documents styles: 2D-Maps: DXF Point files: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Models: DXF, XML What components are mounted on my equipment? Depending on your choice of system (with or without positioning, i.e - fj dynamics autosteer review., 2D or 3D), your machine is outfitted with inclination sensors, a controller system, and a display/operating panel.

Lots of software and hardware remedies exist to aid establish a device's existing position on the earth and compare it with a wanted layout surfaceand building and construction drivers can do more to utilize the benefits. Device control is making use of different placing sensors and a display to provide the operator with a referral between the position of the bucket or blade and the target grade.

Depending on the configuration, device control systems can provide the driver with an easy visual guide to pail or blade setting, or can automatically relocate the blade to grade by speaking to the device's hydraulics - https://au.enrollbusiness.com/BusinessProfile/6851844/Sheroz%20Earthworks. There are machine control systems available for nearly any kind of machine: , dozers, excavators, soil and asphalt compactors, scrapes, leaners, milling equipments, and pavers

The Single Strategy To Use For Sheroz Earthworks

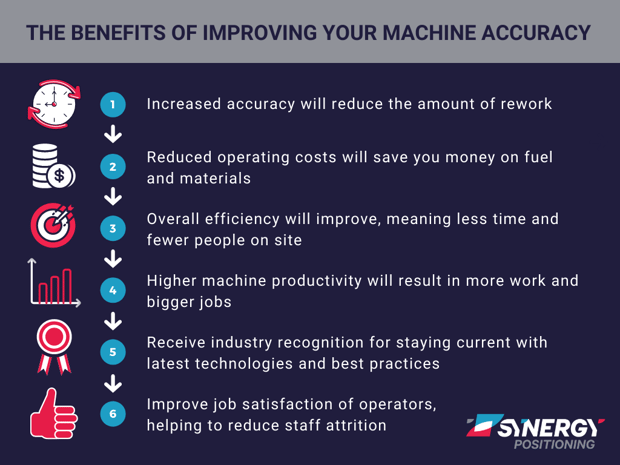

Some advantages consist of minimized rework, enhanced task performance, and reduced checking prices. Machine control can likewise help enhance productivity and decrease total prices. view publisher site This innovation is changing the way the building industry works. Building and construction tools without device control will certainly become a distant memory and the advantages obtained from it will be countless.

Trimble machine control systems give a myriad of advantages to anyone that utilizes earthwork machinery and, at EarthCalc, we can supply you with 3D apply for your equipment control-enable tools. Uncertain if equipment control deserves the cost? Consider the complying with reasons that you need to consider this choice.

Making use of general practitioner aligned with your 3D style data, these systems practically guarantee that you will remove or place the right quantity of product at the building and construction site. On the majority of building and construction sites, rework is a typical and frustrating truth, however with Trimble machine control, you can eliminate the need for rework.

The 10-Minute Rule for Sheroz Earthworks

Typically, with Trimble device control, you can get rid of excess tools at a specific task site. For instance, a task that could have required the usage of three or four pieces of digging deep into tools currently could need only 2 items of devices to complete the exact same job in less time. This enables you to relocate your tools to an additional job website and handle numerous jobs at one time.

Report this page